Effective grounding is essential for ensuring electrical safety and system stability in various applications. Earthing electrodes, also known as grounding rods or electrodes, play a vital role in creating a low-resistance path for fault currents to safely dissipate into the ground. Among the different types of earthing electrodes, those made from galvanized iron (GI) are widely used due to their excellent conductivity, durability, and corrosion resistance. In this blog post, we will delve into the significance of GI earthing electrodes, and their applications, and explore the various types available.

Importance of GI Earthing Electrodes

GI earthing electrodes offer several advantages

GI earthing electrodes find widespread application in various industries and sectors. Some of the key areas where these electrodes are extensively used include:

- Power Generation and Distribution: GI earthing electrodes play a crucial role in power plants, substations, and distribution networks. They provide a safe path for fault currents, protecting equipment and personnel from electrical hazards.

- Telecommunications: The reliable earthing of telecommunication infrastructure, such as cell towers and data centres, is critical for the proper functioning of communication systems. GI earthing electrodes effectively ground equipment and protect against lightning strikes and static electricity.

- Industrial Sector: Industrial facilities often deal with high-power equipment and machinery, making proper earthing vital. GI earthing electrodes ensure the safe dissipation of fault currents, reducing the risk of electrical accidents and equipment damage.

Applications of GI Earthing Electrodes

- Excellent Conductivity: Galvanized iron has high electrical conductivity, allowing it to efficiently conduct fault currents to the ground. This conductivity helps maintain the potential of the electrical system at a safe level, minimizing the risk of electric shock.

- Durability and Corrosion Resistance: The galvanization process involves coating the iron with a layer of zinc, which provides excellent protection against corrosion. This ensures the longevity of GI earthing electrodes, even in harsh environmental conditions.

- Low Maintenance: GI earthing electrodes require minimal maintenance due to their corrosion resistance. Regular inspections and occasional cleaning are usually sufficient to ensure their optimal performance.

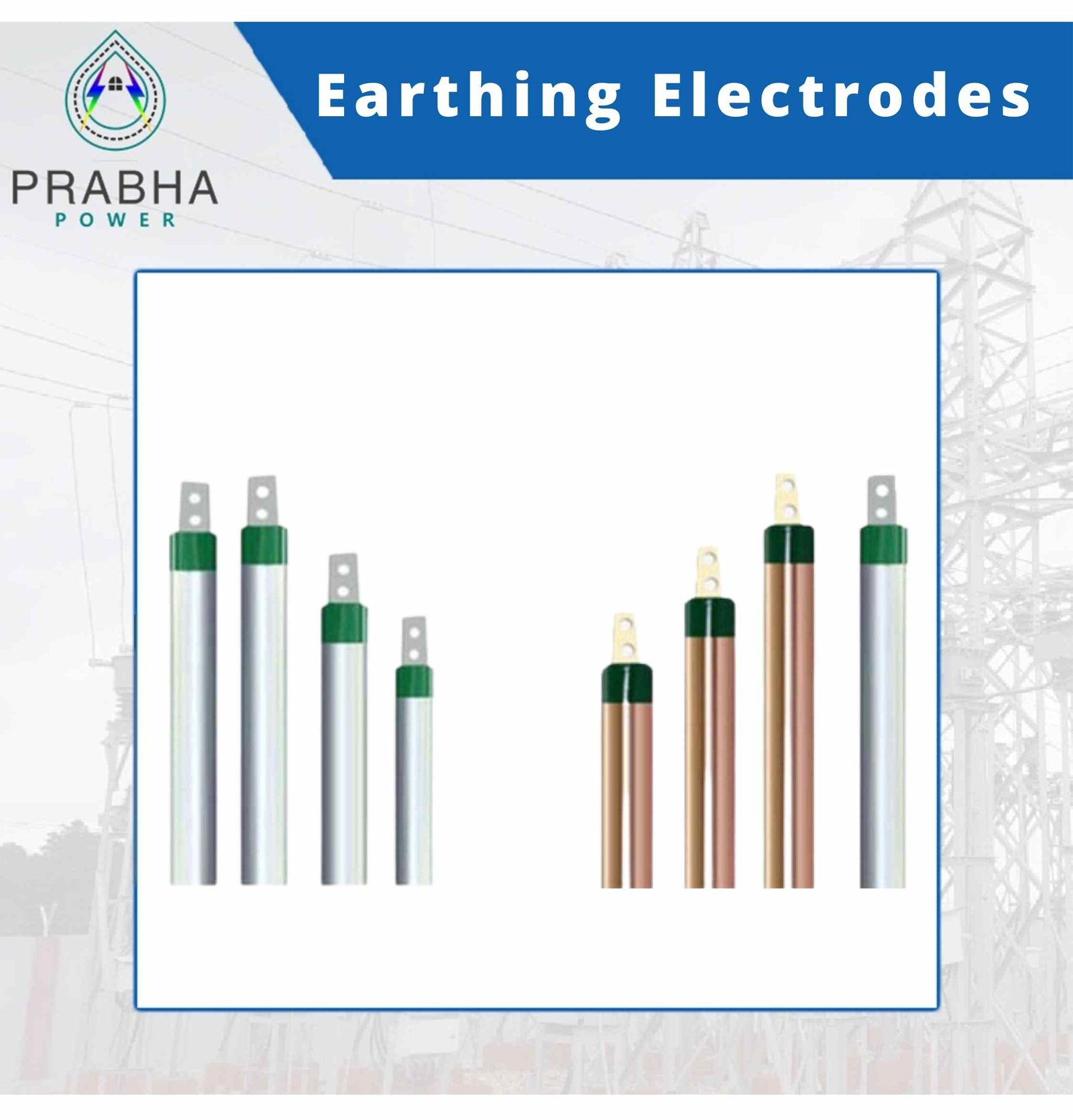

Types of GI Earthing Electrodes

GI earthing electrodes are available in various shapes and designs to suit different applications. Some common types include:

Conductive Plates

These are flat plates made of galvanized iron, buried in the ground to provide a large surface area for efficient dissipation of fault currents. Conductive plates are often used in areas with limited space or rocky terrain.

Conductive Rods

GI conductive rods are cylindrical in shape and installed vertically into the ground. They are commonly used in residential, commercial, and industrial applications and are known for their ease of installation.

Metal Water Pipes

Other Conductors

Conclusion

GI earthing electrodes are essential components of effective earthing systems in electrical installations. By providing a low-resistance path for fault currents, these electrodes enhance electrical safety, protect equipment, and ensure system stability. Their conductivity, durability, and corrosion resistance make them a preferred choice in various applications, including power generation, telecommunications, and industrial sectors. Whether it’s a conductive plate, rod, or metal water pipe, the selection of the appropriate GI earthing electrode depends on factors such as soil conditions, installation requirements, and specific project needs.