LT XLPE cables are foundational in modern electrical systems as high-quality cables with great insulation and high thermal limits spanning multiple applications. From wiring your home to the largest industrial use, they offer a safer and more efficient version of previous low-tension, cross-linked polyethylene insulated cable options.

As demand grows, it is no surprise that LT XLPE cables are designed to provide reliable performance in the most challenging conditions. When it comes to electrical installations, the selection of cables to maximize efficiency and safety and extend the life of infrastructure is key. LT XLPE cable is among the most favoured options for low-voltage electrical systems today.

Across industries, these cable types are achieving preferred status based on their solid build features and wide-ranging applications. Do you want to learn more about LT XLPE cables, why they are emerging as a favoured product, or how they fit into what would be your real-world use? This blog will provide this essential info. We will cover everything from LT XLPE design, advanced features, to detailed examples of use.

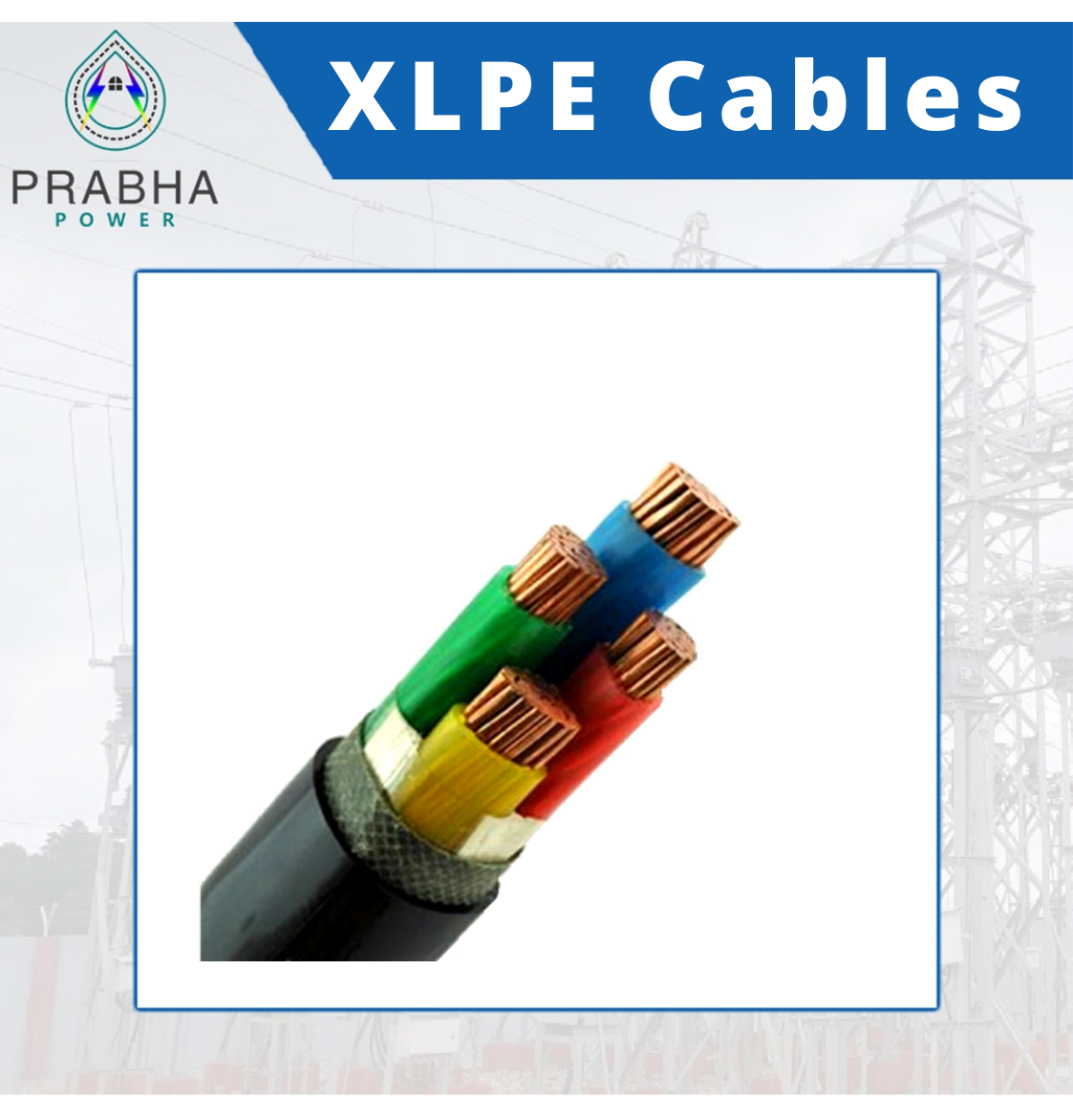

What Are LT XLPE Cables?

Let’s break it down. “LT” stands for “low-tension”, and these are cables designed to work in systems below 1.1 kV. “XLPE” stands for cross-linked polyethylene, which is a specific type of insulation that increases thermal and mechanical performance. LT XLPE cables are power cables that were meant to have a better capability for low-voltage applications. LT XLPE cables have struck a chord in the marketplace for good reason.

Whether it be a new residence, a commercial property, or an industrial facility, these cables meet all the requirements for safety, performance, and longevity. Concerning durability, the structures of LT XLPE cables provide superior performance in adverse conditions, thermal, mechanical and environmental; simply put, they are designed to last longer, perform better in adverse conditions, and withstand thermal, mechanical, and environmental conditions better than traditional PVC-insulated cables.

We can say that LT XLPE cables are power cables designed for low-voltage applications, and they are durable, flexible, and offer excellent electrical performance. They have essentially replaced older PVC-insulated cables, which is a nice way of saying their functional properties are superior in nearly every environment.

Why LT XLPE Cables Have Gained Popularity

LT XLPE cables have become very popular due to their outstanding performance and flexibility. With high dielectric strength and excellent insulation performance, LT XLPE cables allow for efficient power transfer with minimal energy losses. They can be used in both domestic and industrial use cases because they can withstand moisture, chemicals, and extreme temperatures.

These features make LT XLPE cables a robust solution with a low total cost of ownership, little maintenance, and durability in the face of challenging application conditions. It is easy to see why these cables are a preferred solution across different segments.

Here are the advantages of LT XLPE Cables:

- Lightweight and easy to install

- Require little maintenance

- Low Cost

- Higher current carrying capacity

- Better fire resistance

Regardless of whether you have a residential complex, commercial building, or industrial plant, LT XLPE cables will meet your power distribution needs.

Features of LT XLPE Cables

The distinct characteristics of LT XLPE cables are ideal for applications in multiple fields. Excellent thermal resistance allows LT XLPE cables to withstand extreme temperatures, so performance is guaranteed even if conditions are harsh. Sure, they have moisture resistance, but they can take on chemicals and mechanical operators, too.

Excellent electrical properties, a higher capacity for current load, and accepted fire safety features make LT XLPE cables effective and safe in residential and industrial applications. All of these parts add up to a long lifespan and low maintenance.

Let’s look at some defining characteristics that make LT XLPE cables a trusted choice.

1. High Thermal Resistance

- Can withstand typical service temperatures of 90 °C

- Also rated for short-circuit conditions up to 250 °C

- Excellent thermal stability enables indoor and outdoor applications.

2. Moisture and Chemical Resistance

- The properties of XLPE insulation provide a complete moisture barrier.

- XLPE insulation also demonstrates resistance to oils, greases, acids, and other industrial chemicals.

- It’s ideal for chemical plants, refineries, and coastal environment applications.

3. Higher Current Carrying Capacity

- Can carry greater current than conventional PVC-insulated wires.

- Minimizes energy losses and enhances system efficiency.

- Beneficial for heavy-duty use.

4. Flame Retardant and Low Smoke Emission

- Slows the spread of flames.

- Produces low amounts of toxic smoke, which is very important when in confined spaces.

- Increases safety in less common areas, such as buildings, tunnels, and metro stations.

5. Mechanical Strength and Flexibility

- It has elasticity and can be bent, vibrated, and mechanically impacted.

- It is straightforward to transport, route, and install.

6. Excellent Electrical Properties

- Excellent insulation resistance and a low dielectric constant.

- Ensures power is transmitted safely, without excessive power loss.

- Provides a stable and interference-free supply.

Types of LT XLPE Cables

The different types of LT XLPE cables all matter because each was developed to meet specific demands based on environment and other variables, load capacity, and drive the need for the type of protection required for the electrical system.

Whether it is just a single-core cable designed for power transmission purposes or an armoured cable for a location with mechanical risks, the proper type will be selected to provide the best performance and safety.

The range of types available also provides diversity and flexibility to ensure that cables can be applied to applications such as residential buildings or harsh industrial environments. These types were developed to ensure that users understand the types available for both functions and applications for the requirements to assist users in determining the best options regarding cost and longevity.

LT XLPE cables come in a range of types based on construction and intended application:

1. Single-Core and Multi-Core Cables

- Single-Core: Suitable for industrial applications that require high current.

- Multi-Core: Commonly used in residential and commercial applications for power distribution.

2. Armoured and Unarmoured Cables

- Armoured cables: Have an additional layer of steel wire or tape over the insulation for protection from physical damage.

- Unarmoured cables: Used in safe, indoor environments where there is no requirement for mechanical protection.

3. Aluminium and Copper Conductor Cables

- Aluminium conductors are lightweight and the cheapest.

- Copper conductors have higher conductivity and longer life, but cost more.

Applications of LT XLPE Cables

The true versatility of LT XLPE cables is their ability to serve many industries, sectors, and applications and to perform consistently in each of them. Whether it’s industrial heavy machinery, commercial electrical connections, or residential use, LT XLPE electrical cables deliver long-lasting durability and performance.

Having the ability to withstand moisture, environmental chemicals, and extreme temperatures makes these cables suitable for hazardous applications such as power generators and other electrical systems found in oil refineries, commercial renewable power systems, and lighting systems within transportation networks.

Both inside and outside, the ability of LT XLPE cables to adapt and benefit all sectors with their capability of delivering power as they require is impressive!

Here are a few examples of where LT XLPE cables really shine:

1. Industrial Plants and Factories

- Provides power to heavy equipment and automatic systems.

- Operates in very high-temperature and corrosive situations consistently.

2. Commercial Buildings

- Powering electrical systems throughout a large building and distributing power in shopping centres and office buildings.

- Provides safety and reliability for fire-rated conditions.

3. Residential Projects

- Powering up lighting, air conditioning units, and household appliances

- Provides consistent and secure electricity delivery

4. Infrastructure and Public Projects

- The application also applies to significant construction efforts like bridges and flyovers, airports, and railway expansions.

- Fully weatherproof. Can withstand rain, heat, and mechanical loads.

5. Renewable Energy Installations

- Commonly applicable in many solar parks and wind power systems.

- Fully UV and weather resistant.

6. Oil & Gas Industry

- Best suited for refineries and gas plants, offshore rigs, etc.

- Completely resistant to oils, gases, and other corrosives.

7. Railway and Transport Networks

- Used for signalling, lighting, and communications in railways and transport networks.

- Will perform adequately in a high-vibration / high-wear area.

Benefits of Using LT XLPE Cables

To summarise, here are the main benefits that come with using LT XLPE cables:

- Long working life – 30 to 40 years.

- High resistance to heat, moisture, and chemicals. Minimal or no maintenance.

- Environmentally friendly with low emissions in a fire.

- Improved electrical efficiency and performance.

- Suitable for a wide variety of environments and applications

- Enhanced safety in fire-sensitive or moisture-prone environments.

LT XLPE vs PVC Cables: What’s the Difference?

When deciding between LT XLPE and PVC cables, it’s important to recognize how they perform and the lengths of their durability. In terms of durability, LT XLPE cable is better than PVC cable, by far, in most respects.

LT XLPE can withstand elevated temperature ratings, up to 90°C during normal operations and even higher ratings under short-circuit conditions, while PVC cable only has a maximum temperature rating of 70°C. LT XLPE is also resistant to more chemicals and moisture, making it moa re viable option in harsher environments.

While considering current-carrying capacity, LT XLPE also has better performance than PVC in this area, while also being one of the more efficient cable designs, while losing surprisingly less energy to heat than PVC. Not only is LT XLPE more flexible than PVC, but LT XLPE can be guaranteed for a longer life span, about 30-40 years, not to mention that they have enhanced flame-retardant capabilities than PVC, which decidedly increases overall safety.

While PVC cable may be more cost-effective upfront, LT XLPE cable can be far more cost-effective over time, because of its lifespan and performance.

Installation and Handling Tips

To ensure the optimal performance of LT XLPE cables, one should make sure that the installation follows the best practices:

- Select cables to match the install environment; tempered for outdoor or harsher environments.

- Don’t bend or pull too heavily on the cables during installation.

- Don’t lay cables in soak conditions or highly chemically active areas, unless rated to do so.

- Let the qualified electricians do the splicing and termination to avoid performance issues.

- Use the appropriate cable glands, lugs, and accessories to protect the insulation.

Conclusion

LT XLPE cables stand out as a superior choice for modern electrical systems, offering unmatched durability, safety, and efficiency across diverse applications. From residential projects to heavy-duty industrial plants, these cables deliver reliable performance under challenging conditions, ensuring long-term cost savings and minimal maintenance.

Choosing the right cable is critical for optimizing your electrical infrastructure, and LT XLPE cables from Prabha Power in Guwahati offer the perfect blend of advanced technology and practical benefits. Whether you’re powering a commercial complex or a renewable energy system, these cables provide the flexibility, fire resistance, and environmental resilience required for today’s demanding applications.

Power up your project with confidence—call us today at 093948 79486 to explore our range!