Low voltage systems, operating at voltages up to 1.1kV, are the cornerstone of power distribution across residential, commercial, industrial, and infrastructure applications. These systems demand cables that deliver safety, efficiency, and reliability to meet the needs of a power-dependent world. LT XLPE (Low Tension Cross-Linked Polyethylene) cables have become the preferred choice for such systems, offering unmatched performance and durability.

But what makes LT XLPE cables stand out as the ideal solution for low voltage applications? Their unique combination of thermal resilience, electrical efficiency, and mechanical strength ensures consistent power delivery while prioritizing safety and cost-effectiveness. This blog explores the key reasons why LT XLPE cables are the optimal choice for modern low voltage systems.

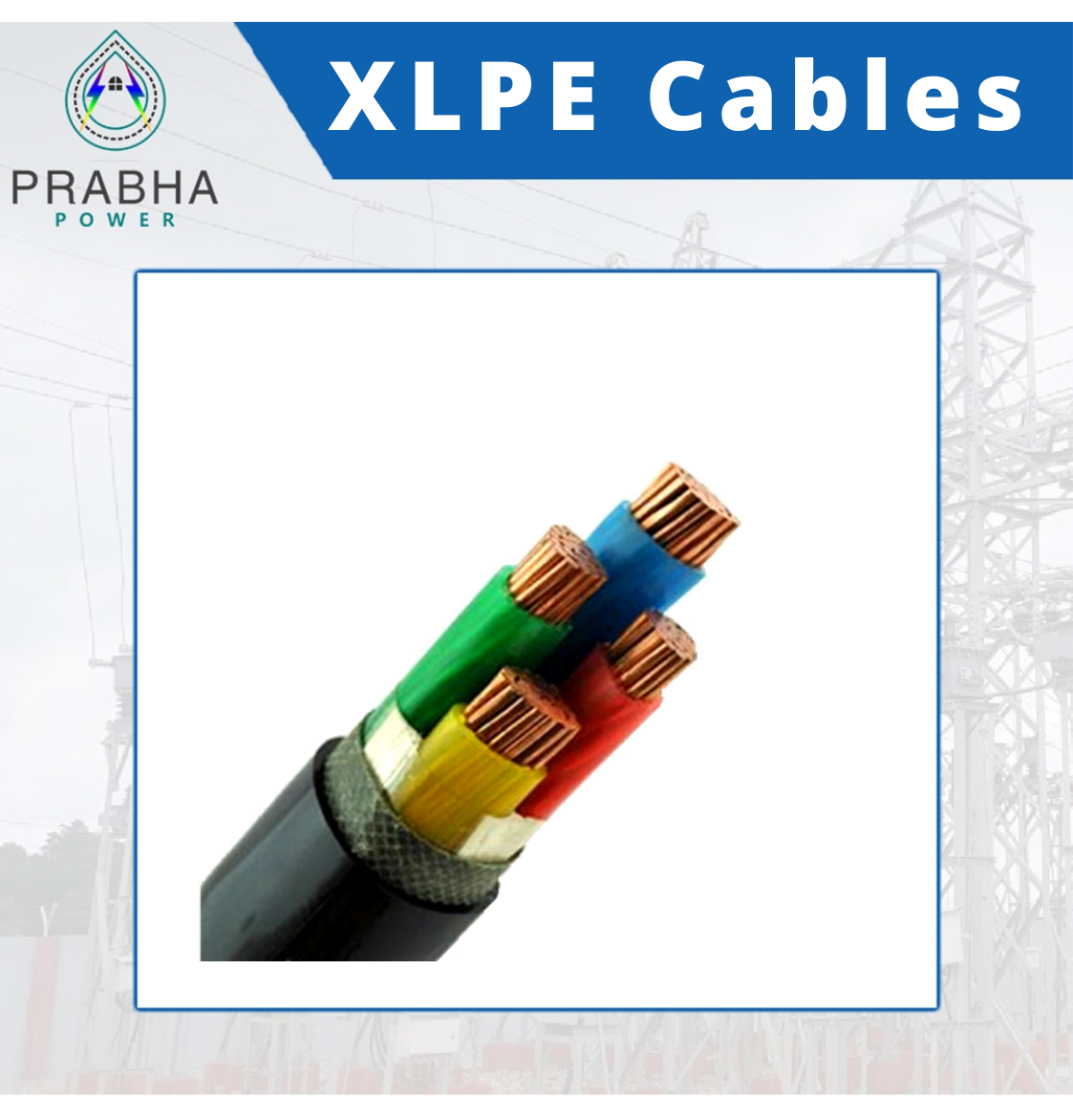

Understanding LT XLPE Cables

LT XLPE cables are specialized low-tension cables designed for voltages up to 1.1kV, using cross-linked polyethylene as the insulation material. The cross-linking process chemically bonds polyethylene molecules, enhancing the cable’s thermal, mechanical, and electrical properties. This makes LT XLPE cables robust, efficient, and capable of withstanding challenging conditions, ensuring reliable power delivery in low voltage systems.

Unlike traditional insulation materials, XLPE’s molecular structure provides superior resistance to heat, moisture, and mechanical stress. These characteristics make LT XLPE cables a standout choice for modern electrical installations where performance and safety cannot be compromised.

Why LT XLPE Cables Excel in Low Voltage Systems

Low voltage systems require cables that can handle varying electrical loads, environmental stresses, and safety demands while maintaining efficiency. LT XLPE cables are tailored to meet these needs, offering distinct advantages that make them ideal for such applications. Below, we delve into the key reasons why these cables are the preferred choice.

Exceptional Thermal Performance

Low voltage systems often experience fluctuating loads or occasional overloads, which can generate significant heat. LT XLPE cables are designed to operate at higher temperatures—up to 90°C under normal conditions and 250°C during short circuits—compared to PVC cables, which are limited to 70°C. This high thermal tolerance ensures that LT XLPE cables maintain performance and structural integrity even under stress, reducing the risk of insulation failure and enhancing system reliability.

This capability is particularly valuable in environments with high ambient temperatures or where cables are densely packed, such as in industrial control panels or urban infrastructure projects.

Enhanced Electrical Efficiency

Efficiency is a critical factor in low voltage systems, where energy losses can add up over time. LT XLPE cables offer superior electrical properties, including lower dielectric losses and higher insulation resistance compared to PVC cables. These properties minimize energy wastage as heat, ensuring more power is delivered to the intended load.

Additionally, LT XLPE cables have a higher current-carrying capacity and better short-circuit ratings. This makes them ideal for applications requiring stable power delivery, such as lighting systems, HVAC units, and distribution panels, where efficiency directly impacts operational costs.

Robust Mechanical Strength

Low voltage systems are often installed in demanding environments—underground, within walls, or exposed to physical stress. LT XLPE cables are engineered for durability, offering excellent resistance to impact, abrasion, and tensile stress. Their flexibility prevents cracking or fatigue, even in tight or complex installations.

This mechanical robustness reduces wear and tear, ensuring consistent performance and minimizing maintenance needs. For example, in underground installations or industrial settings, LT XLPE cables withstand physical stresses that could degrade less durable cables.

Uncompromising Safety Standards

Safety is paramount in low voltage systems, where faults can lead to fires, equipment damage, or operational downtime. LT XLPE cables are designed with safety in mind, offering several protective features:

- Fire Resistance: XLPE insulation is less prone to catching fire and emits minimal toxic fumes compared to PVC, making it safer for confined spaces like commercial buildings or tunnels.

- Moisture Resistance: XLPE’s hydrophobic nature ensures consistent insulation performance in humid or wet environments, reducing the risk of short circuits.

- Chemical and UV Stability: LT XLPE cables resist degradation from chemicals, oils, and UV exposure, making them suitable for industrial and outdoor applications.

These safety features make LT XLPE cables a reliable choice for critical low voltage systems where downtime or hazards are unacceptable.

Long-Term Cost Efficiency

While LT XLPE cables may have a higher upfront cost than traditional PVC cables, their longevity and low maintenance requirements make them cost-effective over time. With a service life of 30–40 years under optimal conditions, these cables reduce the need for frequent replacements. Their resistance to environmental factors like moisture, chemicals, and UV rays further lowers maintenance and repair costs.

Additionally, the energy efficiency of LT XLPE cables translates to lower operational expenses, making them a smart investment for projects prioritizing long-term value.

Tailored for Diverse Low Voltage Applications

LT XLPE cables are versatile, meeting the demands of various low voltage systems without requiring extensive customization. Their adaptability makes them ideal for:

- Residential Wiring: From single homes to apartment complexes, LT XLPE cables provide safe and reliable power for lighting, appliances, and service connections.

- Commercial Installations: In offices, malls, and hospitals, these cables support critical systems like emergency lighting, fire alarms, and backup power.

- Industrial Settings: LT XLPE cables power machinery, control systems, and HVAC units in manufacturing plants, ensuring uninterrupted operations.

- Infrastructure Projects: From street lighting to railway signaling, their durability and environmental resistance make them perfect for large-scale applications.

This versatility ensures that LT XLPE cables can be seamlessly integrated into any low voltage system, delivering consistent performance across diverse use cases.

Environmental and Sustainability Benefits

In an era of increasing environmental awareness, LT XLPE cables align with sustainable practices. They are often halogen-free, producing less toxic smoke in the event of a fire, which enhances safety and reduces environmental impact. Their energy-efficient design minimizes power losses, contributing to lower carbon footprints. Additionally, their long lifespan reduces material waste, making them a greener choice for eco-conscious projects.

For organizations aiming to meet green building standards or reduce environmental impact, LT XLPE cables offer a practical and effective solution.

Selecting the Right LT XLPE Cable

Choosing the appropriate LT XLPE cable for a low voltage system requires careful consideration of several factors:

- Voltage Compatibility: Ensure the cable is rated for voltages up to 1.1kV, suitable for low voltage applications.

- Conductor Type: Copper offers superior conductivity but is costlier, while aluminum is lighter and more economical.

- Armouring: For installations exposed to physical stress, such as underground or industrial settings, opt for armoured cables for added protection.

- Sheathing: In harsh environments, select cables with sheaths resistant to chemicals, oils, or extreme temperatures.

- Standards Compliance: Verify that the cables meet national (e.g., IS) or international (e.g., IEC, BS) standards, and look for third-party certifications for quality assurance.

By aligning cable specifications with project requirements, you can maximize performance and safety.

LT XLPE vs. PVC: Why XLPE Stands Out

Compared to traditional PVC cables, LT XLPE cables offer significant advantages for low voltage systems. Their higher temperature tolerance, better mechanical strength, and superior moisture resistance translate to enhanced reliability and safety. While PVC cables may suffice for basic applications, they lack the durability and efficiency of XLPE, often requiring more frequent maintenance and replacements.

For projects where long-term performance and minimal upkeep are priorities, LT XLPE cables provide a clear edge, delivering value through improved safety, efficiency, and longevity.

Real-World Impact: LT XLPE Cables in Action

A recent urban infrastructure project in India highlights the effectiveness of LT XLPE cables. A major metro rail system replaced traditional PVC cables with LT XLPE cables for its low voltage power distribution. The result was improved operational efficiency, enhanced safety, and reduced maintenance costs. The cables withstood constant voltage fluctuations and high moisture levels in underground tunnels, proving their reliability in real-world conditions.

This example underscores why LT XLPE cables are increasingly chosen for critical low voltage systems, where performance and safety are non-negotiable.

Making the Smart Choice for Low Voltage Systems

LT XLPE cables are the ideal solution for low voltage systems due to their unmatched combination of thermal performance, electrical efficiency, mechanical durability, and safety features. Their ability to deliver reliable power in diverse and demanding environments makes them a versatile and future-proof choice. By choosing LT XLPE cables, you invest in a solution that ensures long-term performance, reduces operational costs, and aligns with sustainability goals.

For high-quality LT XLPE cables tailored to your needs, trust Prabha Power. With a commitment to safety, reliability, and excellence, Prabha Power offers a wide range of electrical solutions for residential, commercial, industrial, and infrastructure projects.

Contact Prabha Power at 093948 79486 to explore the right cable solutions for your low voltage system and build a smarter, safer power distribution network.